- Model

- Specifications

- Features

- Advantage

- Accessories

Model

| Model | Super / Upure | Universal | Advanced | |

|

Operating surface Dimensions (mm) L / W / H |

Single-station (single-sided) |

1220×750×900 |

1220×750×900 | |

| Double-station (single-sided) |

2440×750×900 1800×750×900 |

2440×750×900 1800×750×900 |

||

| Double-station (opposite) | 1220×1000×900 | 1220×1000×900 | ||

| Triple gloves (single-sided) |

1500×750×900 1800×750×900 |

1500×750×900 1800×750×900 |

||

| Three-station (single-sided) | 3660×750×900 | 3660×750×900 | ||

| 4-station (single-sided) | 4880×750×900 | 4880×750×900 | ||

| 4 stations (opposite) | 2440×1000×900 | 2440×1000×900 | ||

| 6 stations (opposite) |

3660×1000×900 3660×1200×900 |

3660×1000×900 3660×1200×900 |

||

| 8 stations (opposite) |

4880×1000×900 4880×1200×900 |

4880×1000×900 4880×1200×900 |

||

| 12 stations (opposite) | 7320×1000×900 | 7320×1000×900 | ||

| Control system | Siemens S7 | Siemens S7 | Siemens S7 | |

| touch screen | Siemens S7′′ touchscreen | Siemens S7′′ touchscreen | Siemens S7′′ touchscreen | |

| Purification columns | Column | Column | Double columns | |

| Fans | 90 m³ / h | 90 / 145 / 180 m³ / h | 90 / 145 / 180 m³ / h | |

| vacuum pump | 8 m³ / h | 8 / 12 / 16 m³ / h | 8 / 12 / 16 m³ / h | |

| Water indicators | <1PPM | <1PPM | <1PPM | |

| Oxygen index | <1PPM | <1PPM | <1PPM | |

| apply |

R&D For university research institutes |

Versatile Suitable for research and small-scale production |

Production Suitable for efficient large-scale production |

|

Specifications

|

Product Specifications: |

||

|

Glove box body |

||

|

Box |

Material: 304 stainless steel, thickness 3mm |

|

|

Outer surface: 304 stainless steel |

||

|

Inner surface: brushed surface of oil film |

||

|

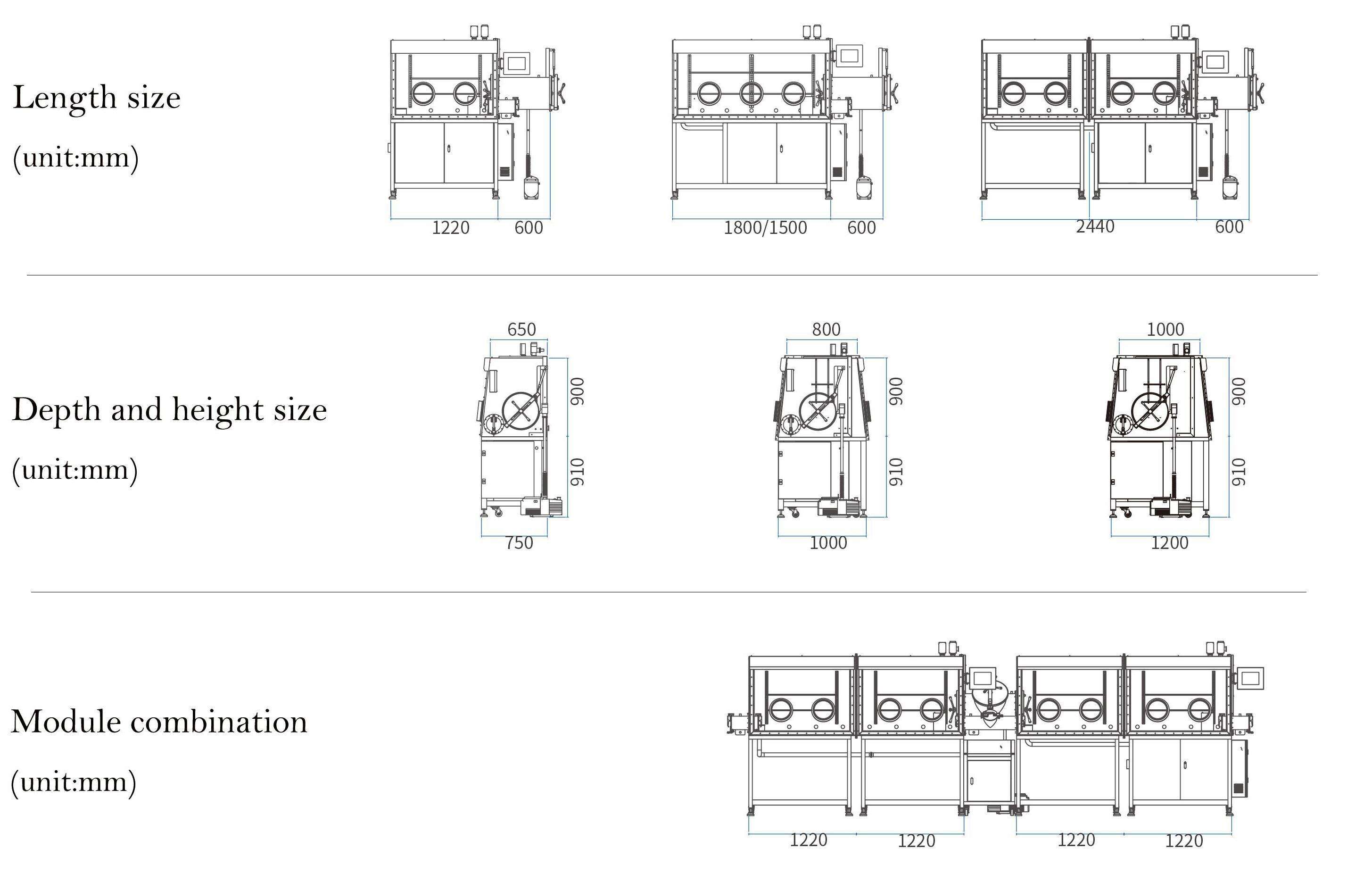

Sizes: Optional lengths 1500, 1800, 2440, 3660, 4880mm Available depths of 750, 1000, 1200mm Height 900mm |

||

|

Front window |

Tilt window: transparent tempered safety glass, thickness 8mm |

|

|

Glove mouth |

The material is POM or aluminum: O-ring seal |

|

|

glove |

Butyl rubber: thickness 0.4mm, diameter 7'' or 8'' |

|

|

filter |

Specification: 0.3μm, one gas inlet and one gas outlet |

|

|

Shelf |

Material: Stainless steel material, built-in 2 layers, height adjustable |

|

|

Cabinet lighting |

Location: LED light, mounted inside the lampshade |

|

|

interface |

Specifications: DN40KF, several spare interfaces, 1 power interface (220V) |

|

|

Purification unit |

||

|

Purification columns |

Function: gas sealing, water removal, oxygen removal |

|

|

Container material: 304 stainless steel |

||

|

Purification material: copper catalyst 5kg, molecular sieve 5kg |

||

|

Purification capacity: 60L of oxygen and 2kg of water |

||

|

Water oxygen index: <1ppm |

||

|

circulatory system |

Working gases: nitrogen, argon, helium |

|

|

Circulating capacity: integrated fan flow rate of 90m³/h (larger fan flow rate of 145m³/h, 180m³/h can be provided) |

||

|

regeneration |

Operation: PLC automatically controls the regeneration process |

|

|

Regenerative gases: Mixed gases with hydrogen (5%-10% hydrogen) |

||

|

vacuum pump |

Specifications: 8m³/h, 12m³/h |

|

|

Rotary vane pump: with oil mist filter, air vibration control |

||

|

valve |

Main valve: DN40KF, electro-pneumatic angle valve |

|

|

Control valve: solenoid integrated valve |

||

|

Rollover warehouse |

||

|

Large rollover warehouse |

Silo body |

Size: Diameter 360mm, length 600mm (optional diameter 400mm) |

|

Material: 304 stainless steel |

||

|

Surface: The inner surface is the brushed surface of the oil film, and the outer surface is painted or mirrored |

||

|

annex |

Tray: Sliding tray |

|

|

Warehouse door: double door, anodized aluminium material, thickness 10mm vertical operation, with lifting structure |

||

|

Pressure gauge: analog display |

||

|

control |

Operation: Automatic control |

|

|

Small bridging chambers |

Silo body |

Size: Diameter 150mm, length 300mm (optional diameter 100mm) |

|

Material: 304 stainless steel |

||

|

Surface: The inner surface is the brushed surface of the oil film, and the outer surface is painted or mirrored |

||

|

annex |

Warehouse door: double door |

|

|

Pressure gauge: analog display |

||

|

control |

Operation: Manual operation |

|

|

Control system |

||

|

description |

Display: Siemens PLC touch screen |

|

|

Functions: including self-diagnosis, power-off self-start features, with pressure control and adaptive functions, automatic control, cycle control, password protection |

||

|

Pressure control: control the pressure of the box and the transition cabin, the working pressure of the box can be set freely within +/- 15mbar, and the system will automatically protect if it exceeds +/- 16mbar |

||

|

Foot switch: The air pressure in the box can be adjusted by the foot switch |

||

|

Data Memo: Automatically record system data |

||

|

fittings |

||

|

vacuum pump |

Specifications: 8m³/h, 12m³/h, 16m³/h |

|

|

Oxygen analyzers |

Measuring range: 0~1000ppm |

|

|

Dew point analyzer |

Measuring range: 0~500ppm |

|

Features

| Feature/Option | Description |

|---|---|

| 1. Closed Loop Gas Circulation | Inert gas in a closed loop. The gas is circulated by the blower and purifier, H2O, O2 can be removed continuously. |

| 2. Auto Purging | The replacement of the atmosphere inside the glove box can be achieved automatically by the purging valves. |

| 3. Automatic Regeneration | H2O and O2 removal material can be regenerated. The regeneration process can be program controlled. |

| 4. Automatic Pressure Control | The pressure in the glove box is controlled automatically by the Programmable Logic Controller (PLC). Working pressure can be set either between +15mbar and -15mbar or between +12mbar and -12mbar. If the pressure goes over the set range, the system will be protected automatically. |

| 5. Eco Mode | The vacuum pump will be activated automatically when necessary, and will turn off after a period of idle time. Blower frequency will be switched to 25Hz when moisture and oxygen level reaches to less than 1 ppm. |

Advantage

| Feature/Option | Description |

|---|---|

| 1. High Capacity Purifier | Rapid removal of H2O and O2 to less than 1ppm. Long intervals between regeneration cycles. |

| 2. PLC Control and Color Touchscreen HMI | Automatic Purge; Circulation; Regeneration; Pressure control; User Friendly Interface. |

| 3. Long Life Moisture and Oxygen Analyzers | P2O5 Moisture Sensor: Corrosion resistant, Renewable by acid-cleaning if the probe is contaminated by HF or other corrosive environmental exposure.<br>ZrO2 Oxygen Sensor: Solid sensor, long life, can be exposed to air without consumption. |

| 4. Customize a Glove Box Specially for Your Application | Our engineering team can help to turn your idea into a solution. |

| 5. Stainless Steel Gas Pipes and Connectors | All the gloveboxes have been upgraded to stainless steel pipes and connectors with much higher corrosion-proof properties for highly corrosive environments. |

Accessories

Accessories Options: | Other Options: |

Moisture Sensor | Customized box sizes |

Oxygen Sensor | Integrating customer’s instruments into the Glovebox, like evaporator, ALD System and Spin Coater etc. |

Solvent Absorber | Polycarbonate Window(s) |

Heated Antechamber | Quick Release Window(s) |

Refrigerator | Antechamber with interlocking door; |

Cold Well | Small chamber with sliding tray |

Microscope Unit | Antechamber purging only without vacuum |

Ionizer without fan | Antechamber refilling from Gas cylinder instead of box |

Various Feedthroughts | Rectangular Antechamber |

| Flexible shelves – adjustable up & down – adjustable back & forth | |

| 12m3/h Rotary pump | |

| Dry scroll pump | |

| Prompt service |