- Overview

- Features

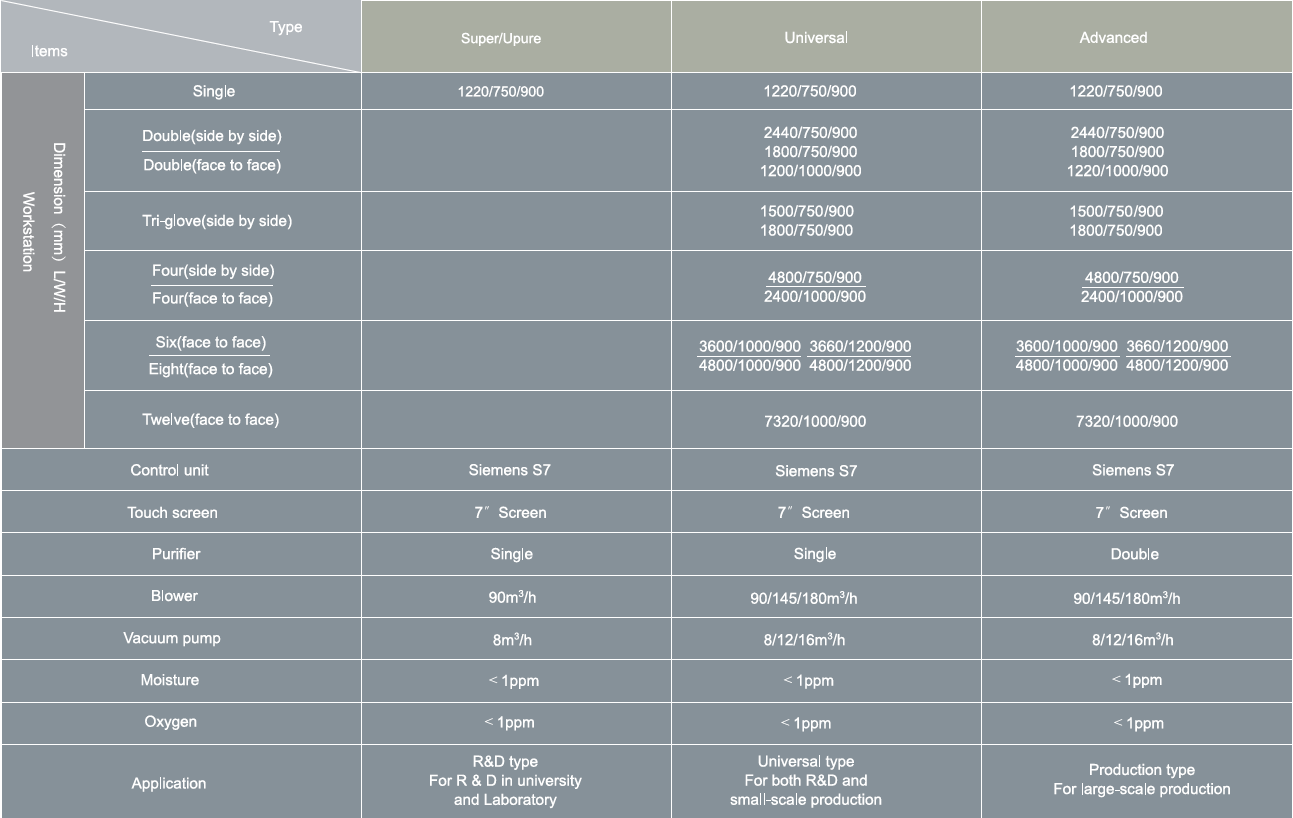

- Parameter Table

Advanced Glovebox

Advanced Glovebox with Dual Purifier is commonly used in full-scale production

With 2 purifiers, when one is performing regeneration, the systems switch to another automatically to achieve continuous production.

From Single to Multiple workstation systems, to be operated either side by-side or face to face with integrated Gas purification system (2 switchable Purifier), PLC controller and HMI, incl. sealed box, in and outward transfer antechamber, inclined operation sides with replaceable sight glass and vacuum pump etc. Attainable purity of the glovebox is H2O

This system includes a large capacity purification system capable of adsorbing 60l of O2 and absorbing 2000g of moisture extending your time between regeneration cycles.

Options&Accessories

Accessories Options

Moisture Sensor

Oxygen Sensor

Solvent Absorber

Heated Antechamber

Refrigerator

Cold Well

Microscope Unit

Ionizer without fan

Various Feedthroughs

Other Options

Customized box sizes

Integrating customer’s instruments into the glovebox, like evaporator, ALD System and Spin Coater etc.

Polycarbonate Window(s)

Quick Release Window(s)

Antechamber with interlocking door

Small chamber with sliding tray

Antechamber purging only without vacuum

Antechamber refilling from Gas cylinder instead of box

Rectangular Antechamber

Flexible shelves – adjustable up & down – adjustable back & forth

12m3/h Rotary pump

Dry scroll pump

Prompt service

Features

Closed Loop Gas Circulation

Inert gas in a closed loop. The gas is circulated by the blower and purifier, H2O, O2 can be removed continuously.

Auto Purging

The replacement of the atmosphere inside the glove box can be achieved automatically by the purging valves.

Automatic Regeneration

H2O and O2 removal material can be regenerated. The regeneration process can be program controlled.

Automatic Pressure Control

The pressure in the glove box is controlled automatically by the Programmable Logic Controller (PLC). Working pressure can be set either between +15mba and -15mba or between +12 mbar and -12 mbar. If the pressure goes over the set range, the system will be protected automatically.

Eco Mode

The vacuum pump will be activated automatically when necessary, and will turn off after a period of idle time. Blower frequency will be switched to 25Hz when moisture and oxygen level reaches to less than 1 ppm

Specifications

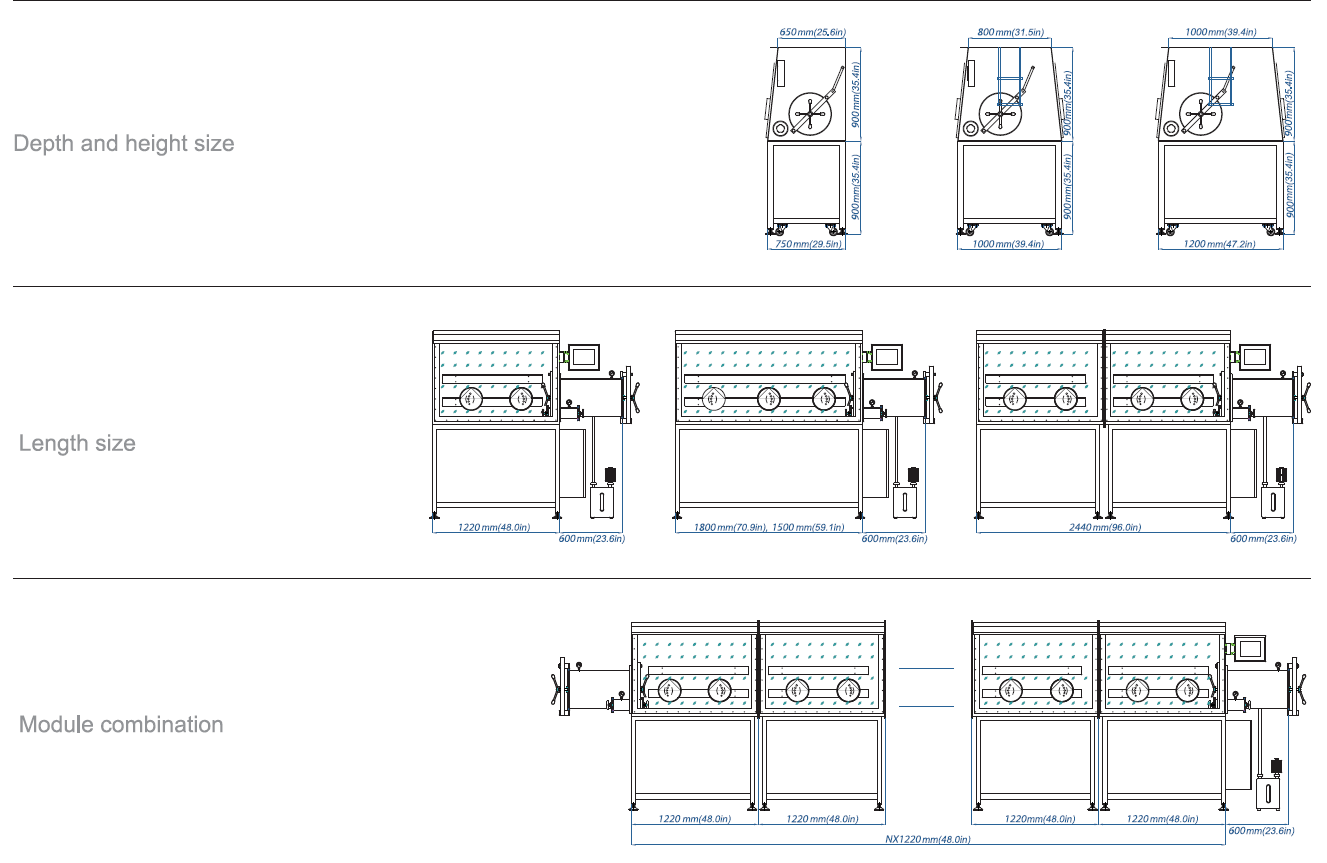

Main Chamber Dimensions

Modular length: 1220mm/1500mm/1800mm/2440mm ( 48.0”/59.1”/70.9”/ 96.0”)

Modular depth: 750mm/1000mm/1200mm (29.5”/39.4”/47.2”)

Modular height: 900m( 35.4”)

Material: Stainless steel type 304, thickness 3mm (1/8”)

Sight Windows: Inclined, Safety Glass, thickness 8mm (1/3”)

Gloves Ports: POM (Polyoxymethylene), 220mm (8.7”) Diameter

Gloves: 8B1532

Dust Filter: HEPA 0.3μ, one gas inlet, one gas outlet

Shelving: Stainless Steel, two fixed shelves (adjustable shelves available)

Lighting: External LED lights, front mounted above sight glass.

Feedthroughs: One power feedthrough, 3 blind-flanges

Large Antechamber

Diameter: 360mm (14.2”) or 400mm (15.7”), Length 600mm (23.6”)

With Sliding tray

Spindle lock door, Vertical operation with lifting mechanism

Automatic operation via solenoid valves

Small Antechamber

Diameter 150 mm (5.9”) or 100mm (3.9”), Length 300mm(11.8”)

Hinged door

Manual operation via hand valve

Dual Purifier

Removal of H2O and O2 to Less than 1 ppm moisture and oxygen

Absorber Unit: 5kg Copper catalyst,5kg Molecular sieve

Capacity to remove oxygen, 60L , moisture 2000g.

Encapsulated Blower: 90m3/h

Regeneration: PLC control all process including heating, introducing mix gas (working gas mixed with Hydrogen 5-10%), etc.

System Control

PLC and HMI: Siemens S7

Vacuum Pump

8m3/h Rotary vane pump with oil mist filter and gas ballast

For more information, please view our specification sheet.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

IS

IS

KA

KA